1.10.2005 I was thinking if I should leave the winding as is and cut the pipe or unwound it and start again. I wanted to keep original design so I decided to do it again. I had a luck and bought quite big spool of 0,355mm enameled wire. I guess there was about 3 km of wire on it so I could wound this pipe twice. New winding process was done without problems and I wound entire pipe. Then I varnished the secondary coil by acrylic spray as usual I did on other coils. Here are some photos of the tiring winding process:

|

|

|

|

|

|

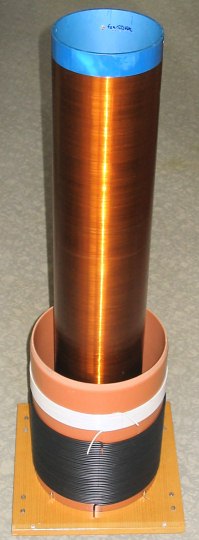

2.3.2006 New secondary coil was idling in a pantry for some time because I didn't have a free time and I couldn't get some piece of bigger pipe for primary coil. Then I finally got a piece of 250mm PVC pipe from my friend. Maybe 300mm would be better but one meter of such pipe costs about 600 CZK. I wound 37 turns of insulated wire with 4 mm2 profile as a primary winding on the pipe and 17 turns of 0,5mm insulated wire above the primary winding as a feedback coil. I plan to use this primary coil for VTTC powered by 1 or 2 GU-81M tubes. More details about windings you can see here.

Because of higher weight of these coils I made the base board of 18mm chipboard instead of my favorite plexiglass. To make a manipulation with MegaTC easier I mounted 4 small wheels on the bottom side of the base board. Primary and secondary coils are not mounted in a hard way but can be removed easily. This will be good for transports or when I will need to replace primary coil accommodated for different kind of driver.

I calculated that resonant frequency of the secondary coil is 107 kHz and then measured 120 kHz. Currently I missing a suitable resonant capacitor for primary tuned circuit. It should be ~ 7 nF / 10 kVAC or some suitable smaller capacitors that I could wire into a MMC. I hope that I will have a luck and buy them somewhere. I'm forward to the first light. I'm curious about spark length compared to my previous smaller TCs at the same input power.